Choosing the right food machine can shape the future of your production line. Whether you're launching a new product line or upgrading existing equipment, your choice will impact everything from efficiency and consistency to staff workload and operating costs.

So how do you make the right call? Start with a clear understanding of your production needs and follow these simple but essential steps.

1. Know Your Product and the Processes It Requires

The type of machine you need depends entirely on what you’re making. For example, producing cupcakes is very different from preparing frozen dumplings or ready-to-eat meals.

Start by mapping out your process: Do you need mixing, forming, filling, cooking, sealing, or packaging? Understanding your workflow helps you identify which parts can be automated and what types of machines are suitable.

If you're just getting started, you may want a compact unit that handles one or two steps. If you’re scaling up, consider a system that connects multiple machines into a streamlined production line. The right machine should fit into your existing flow without creating new bottlenecks.

2. Consider the Scale and Speed of Your Production

One of the most common mistakes is buying equipment that’s either too large or too small for your operation.

For small-scale businesses or startups, a semi-automatic food machine may be enough. These are easy to operate, require less training, and don’t take up much floor space.

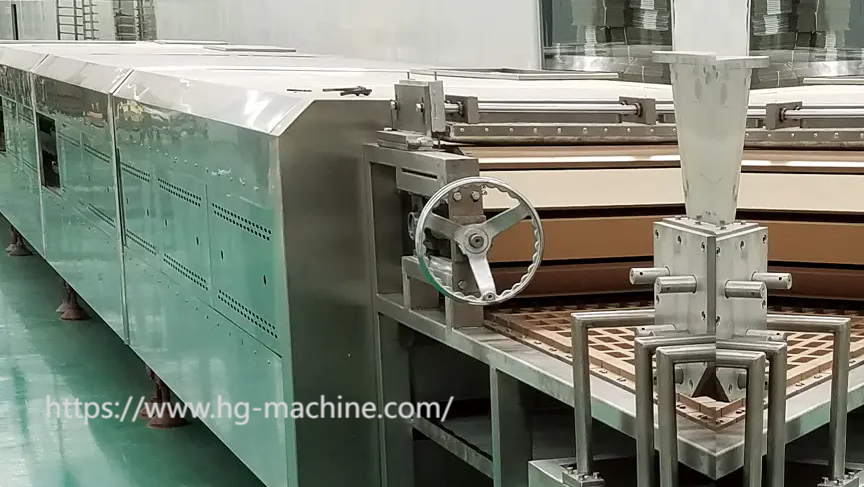

If you’re running a larger factory or expect to scale up quickly, go for a fully automatic model. These machines usually include programmable settings, conveyor integrations, and faster output, allowing you to meet higher demand without adding more staff.

Think ahead: Will your machine still serve you well two or three years from now? Make sure it’s a long-term fit.

3. Ask About After-Sales Support and Future Upgrades

Buying the machine is just the beginning. What happens when you need a replacement part, an upgrade, or help troubleshooting an issue?

A good supplier will offer technical support, fast spare parts delivery, and user-friendly manuals. Some machines also allow remote diagnostics or easy software updates, which are extremely helpful for minimizing downtime.

At hg-machine, our equipment is built not just for performance but also for easy maintenance, smooth training, and long-term service.

The right food machine should do more than run smoothly—it should help your business grow. Take time to evaluate your production goals, team capabilities, and the kind of support you’ll need after installation. Choosing wisely now can save you time, money, and stress down the line.

Ready to explore your options? Visit hg-machine to discover food processing equipment designed for your needs.